Some Known Facts About Customized Titanium Products.

Wiki Article

Customized Titanium Products Can Be Fun For Everyone

Table of ContentsGetting The Customized Titanium Products To WorkHow Customized Titanium Products can Save You Time, Stress, and Money.How Customized Titanium Products can Save You Time, Stress, and Money.Getting The Customized Titanium Products To WorkLittle Known Questions About Customized Titanium Products.All about Customized Titanium Products

The magnesium responds with the chlorine generating liquid magnesium chloride. This leaves pure titanium solid because the melting point of titanium is higher than that of the response. 4 The titanium solid is removed from the reactor by boring as well as after that treated with water as well as hydrochloric acid to get rid of excess magnesium and also magnesium chloride.5 The pure titanium sponge can after that be transformed right into a usable alloy via a consumable-electrode arc furnace. At this point, the sponge is blended with the various alloy additions and scrap metal. The exact proportion of sponge to alloy material is formulated in a lab before manufacturing. This mass is after that pushed into compacts as well as welded together, forming a sponge electrode. Customized Titanium Products.

In this water-cooled, copper container, an electric arc is used to thaw the sponge electrode to create an ingot. Every one of the air in the container is either eliminated (forming a vacuum) or the ambience is loaded with argon to avoid contamination. Commonly, the ingot is remelted one or 2 more times to produce a readily appropriate ingot.

What Does Customized Titanium Products Do?

7 After an ingot is made, it is removed from the heating system and also examined for flaws. The ingot can then be shipped to an ended up goods maker where it can be crushed and produced right into various products.

Reduced sensitivity additionally means it is resistant to rust, making it beneficial for an applications where sea water is entailed. Titanium additionally succeeds at mirroring infrared and ultraviolet radiation, making it useful for space observatory equipment that may be conscious radiation and also as a sunscreen for safeguarding skin.

The Best Guide To Customized Titanium Products

A lot of the residential or commercial properties that make titanium ideal for nuclear power plant condenser pipes also make it a perfect metal nuclear waste storage space containers. One of the most crucial residential or commercial property for a nuclear waste storage container material is reduced sensitivity with other materials or, to put it simply, high corrosion resistance. This suggests that the material can not be conveniently damaged down, which is vital to saving nuclear waste and also protecting against leaks.He called it titanium and later on made the connection that Gregor's example contained titanium. Pure titanium was initially produced by Matthew A. see here Seeker, an American metallurgist, in 1910. Later, in 1932 Titanium steel was initially utilized outside the laboratory setup when William Justin Kroll showed that it can be generated by decreasing titanium tetrachloride (Ti, Cl4) with calcium.

While on the United States side, titanium was thought about a strategic product which extended throughout the period of the Cold Battle by the U.S

The federal government, specifically the Protection National Stockpile Facility, maintained a big accumulation of titanium sponge until it was ultimately depleted in the 2000s.

It is likewise reduced density; regarding 60% the thickness of iron, decreasing lots and stress of larger metals while minimizing the total weight of the objects it is utilized to make. Titanium actually see page has the greatest strength-to-density proportion of any metallic component. The melting factor of Titanium is much greater than Stainless-steel.

The Of Customized Titanium Products

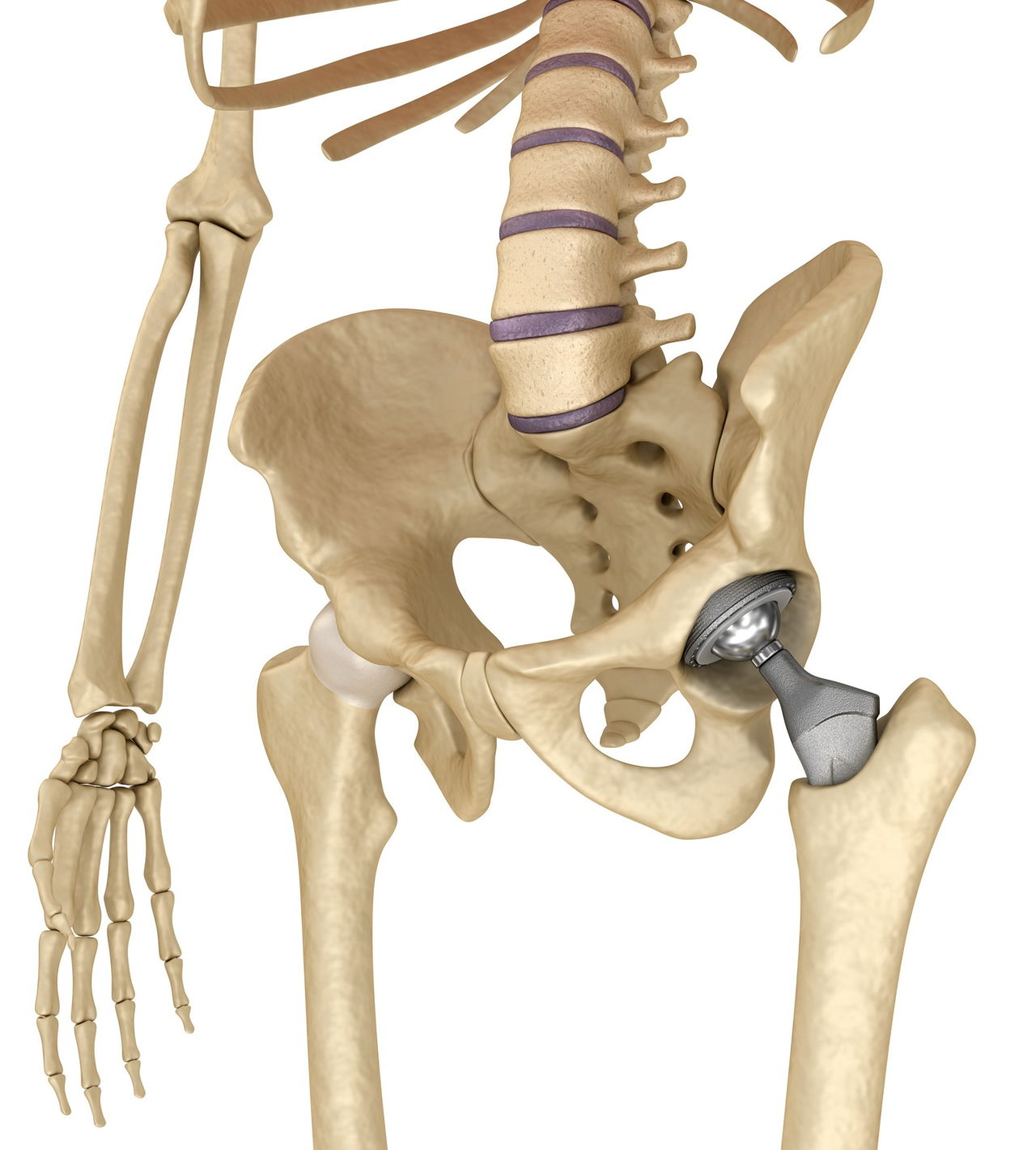

This implies that there is less dimensional change induced by heating the metal when compared to Stainless or Aluminum. This, combined with its superconductive residential properties lends well to use in gadgets such as induction electric motors as well as semiconductor production. Some various other buildings of Titanium consist of: Superb warmth transfer buildings High melting factor - 3,135 levels Fahrenheit (This is 400 degrees above the melting factor of steel and also 200 levels above that of aluminum) A high level of resistance to minerals, acids, and also chlorides Safe - Makes it a candidate for usage in clinical gadgets that are placed in the human body High-degree of electric resistance Considering that titanium is so solid, it can be challenging to cast.However, no matter what the wanted item is, titanium should first be divided out from the ore as well as became pure titanium. This is called the Kroll Process - Customized Titanium Products. The ore begins in a fluidized bed activator which produces detoxified titanium oxide. The cleansed titanium oxide is then oxidized with chlorine to generate titanium tetrachloride.

The product is after that moved right into a stainless steel activator where it is blended with magnesium in an atmosphere of argon. Titanium 3 as well as titanium 2 chlorides (Ti, Cl2) are the results of this action. Titanium 3 and titanium 2 are after that reduced to generate pure titanium as well as magnesium chloride - Customized Titanium Products.

The 8-Minute Rule for Customized Titanium Products

The last item is a titanium "titanium sponge" which is then prepared to undertake more processing which eventually can be made right into bars, plates, sheets, wires, or whatever your application calls for. Right here is what the chain reaction resembles as an equation: Once sponge has been created, the procedure proceeds with the melting of titanium sponge, or sponge plus the master alloy.This was a challenge for us, to say the least. Titanium behaves very in description a different way than stainless steel and nickel alloys. Our production was forced to adapt to the difficulty of generating titanium, creating brand-new strategies and also buying new capabilities to provide titanium metal item that satisfied ours as well as our client's expectations.

There are various sorts of titanium that are ideal for various applications based upon their staminas and buildings. Titanium dioxide is additionally understood as titanium oxide as well as comes in a great white titanium powder. It offers products a bright white tone. It is developed when titanium naturally connects with oxygen.

Report this wiki page